Please note: this information is based on the experience of Luke Hughes; it is not intended to be the final word.

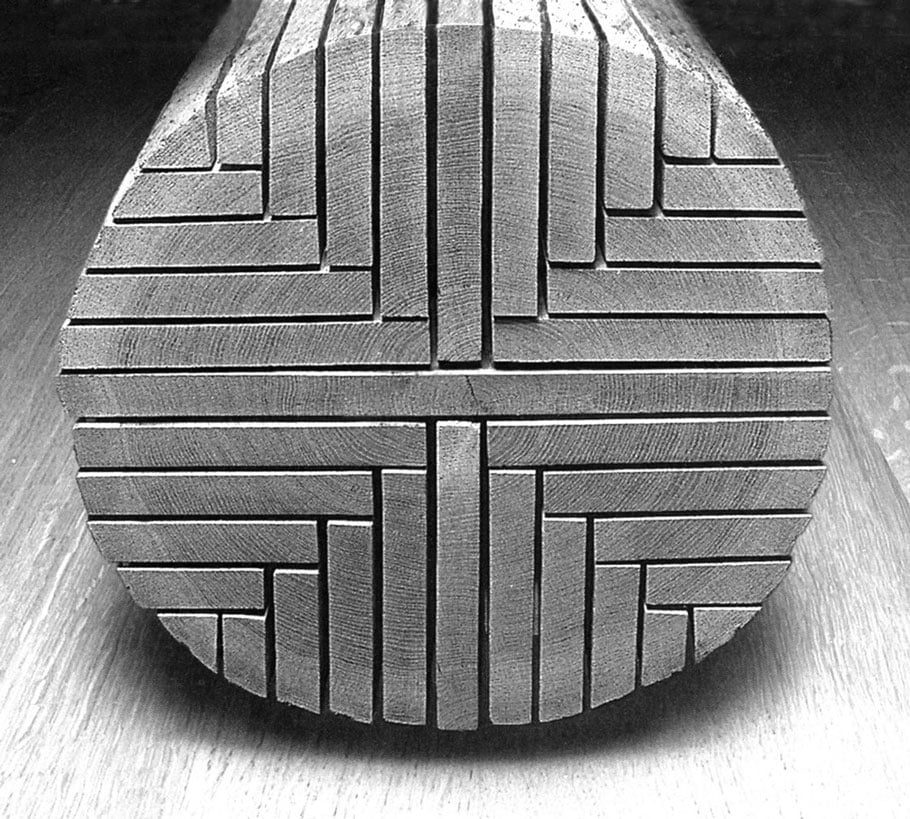

Methods of cutting veneers

Veneer logs are softened by steaming and then sliced to give the maximum yield before being dried and stored in the order they were cut from the log (which greatly assists matching). The most common cuts are:

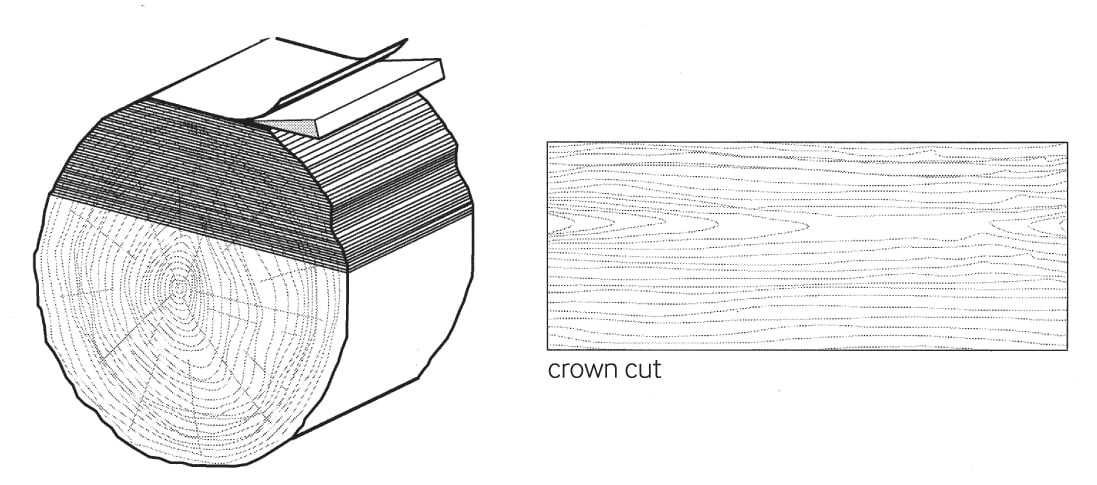

1. Crown cut

The log is sawn lengthwise into two ‘flitches’ (or sections) and then sliced across the growth rings; this produces a pointed loop effect in the middle of each leaf with straighter grain at the edges.

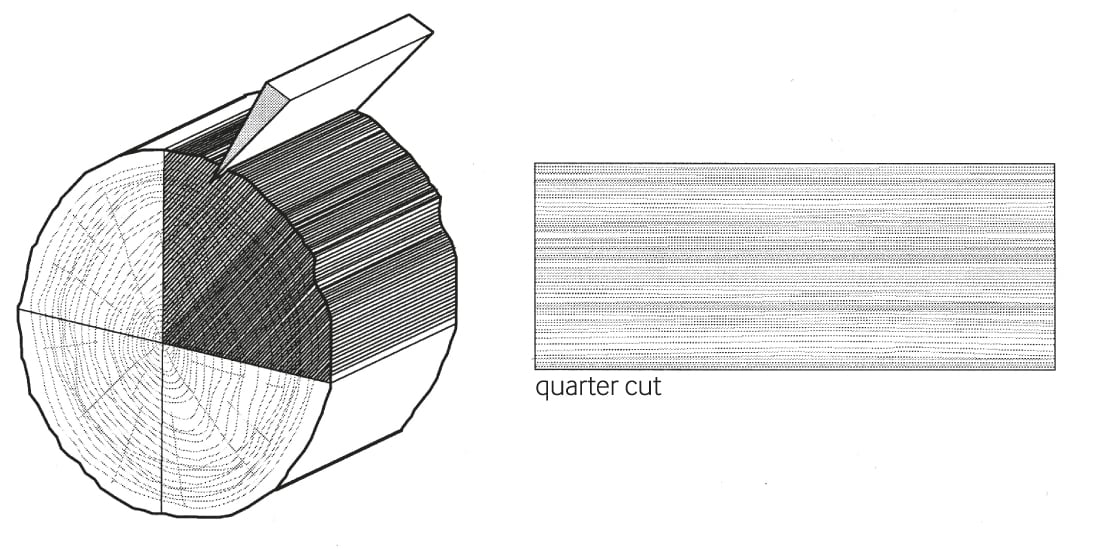

2. Quarter cut

The log is sawn lengthwise into four ‘flitches’ and then sliced at right angles to the growth rings; this produces a straight grain which can be rather stripey.

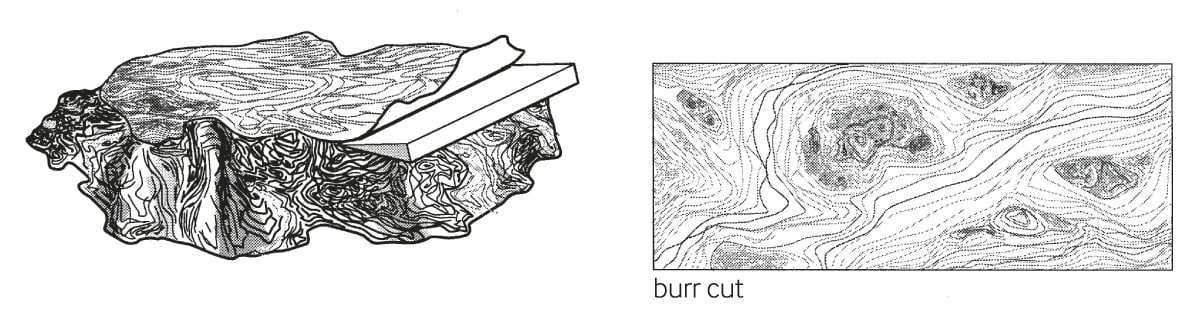

3. Burr cut

The log is cut using a lathe with slices being taken from the circumference of one side of the log; the technique is used for cutting burrs and bird’s eye veneers.

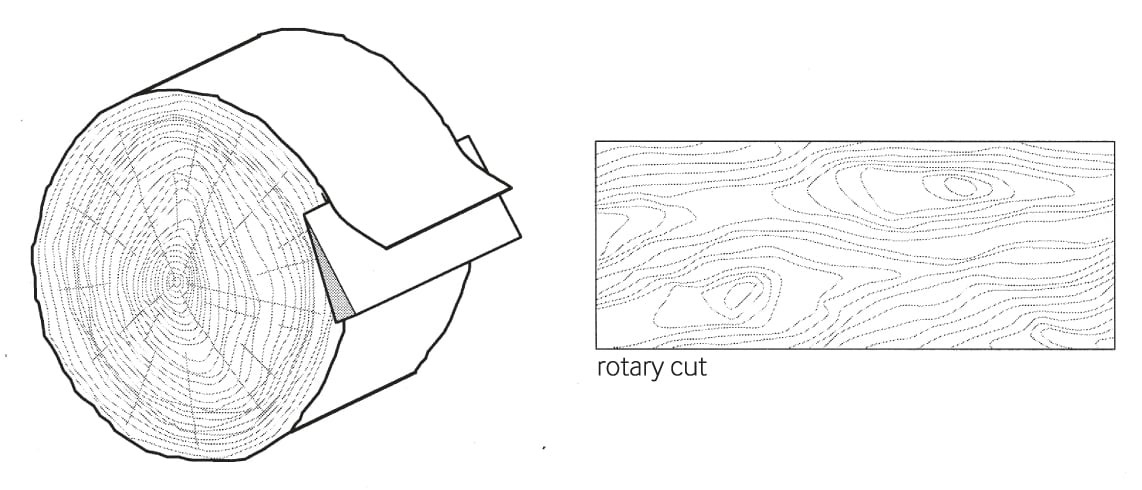

4. Rotary cut

The log is put into a huge lathe and cut continuously around its circumference, more or less parallel to the growth rings; the effect is bland and mostly used for constructional veneers.

Veneer thickness

Conventional veneers are approximately 0.6mm (or around 0.4mm after sanding). Light coloured veneers, such as sycamore, are sometimes only semi-opaque and it is necessary to ‘cross-veneer’ with two layers to fully screen the dark shade of the substrate. Constructional veneers are commercially available at 1.5mm and are used for laminations.

More technical knowledge on working with materials can be found in our eBook 'Furniture factors: Designing around materials'. Click below to download.

Enjoy the article? Delve deeper into Luke Hughes & Company’s place in the Arts and Crafts tradition with the fascinating new book 'Furniture in Architecture' . Available through Thames & Hudson